Water treatment facilities operate in demanding environments where high-performance sealing solutions are essential to maintaining efficiency, safety, and regulatory compliance. Selecting the right gaskets and expansion joints ensures leak-free performance, extends equipment lifespan, and minimizes downtime in critical water processing systems.

At Summers Rubber, we work with industry-leading manufacturers—including Gasket Resources, Garlock, Proco, and Holtz Rubber—to provide top-tier sealing solutions specifically designed for the water treatment sector. Our comprehensive selection of gaskets and expansion joints helps facilities meet strict environmental and safety regulations while optimizing operational performance.

Why Proper Gaskets and Expansion Joints Matter in Water Treatment

- Leak Prevention – Properly chosen and installed gaskets and expansion joints form a secure seal that prevents fluid leaks, reducing water loss, protecting infrastructure, and ensuring uninterrupted facility operations. This is critical for maintaining efficiency and preventing costly repairs due to system failures.

- Chemical Resistance – Water treatment plants handle a variety of chemicals, from chlorine to caustic solutions. Using gaskets and expansion joints with the right material composition prevents premature degradation, ensuring longer service life and reducing the need for frequent replacements.

- Pressure & Temperature Resilience – Water treatment equipment must endure fluctuating pressures and temperature extremes. High-quality gaskets and expansion joints maintain structural integrity under these conditions, preventing ruptures and ensuring reliable performance in both municipal and industrial water systems.

- Vibration & Movement Absorption – Expansion joints play a crucial role in absorbing movement from pipe expansion, contraction, vibration, and misalignment. Without them, excessive pipe stress could lead to premature failures, increased maintenance, and operational inefficiencies.

- Regulatory Compliance – Water treatment facilities must adhere to strict industry regulations, including AWWA, NSF, and EPA standards. Using certified sealing products ensures compliance with safety and environmental guidelines, protecting both workers and the surrounding community.

Summers Rubber’s Trusted Partnerships

Summers Rubber collaborates with leading manufacturers to supply high-quality sealing solutions tailored to the specific demands of water treatment applications:

- Gasket Resources – Specializes in PTFE and high-performance elastomeric gaskets, offering superior resistance to chemicals and extreme temperatures in water processing systems.

- Garlock – Provides premium gasket solutions engineered for exceptional durability, chemical compatibility, and compliance with stringent industry standards.

- Proco Products – Offers high-quality expansion joints designed to handle pipe movement, pressure fluctuations, and vibration, ensuring long-term system reliability.

- Holtz Rubber – Supplies a diverse range of rubber expansion joints ideal for municipal and industrial water treatment applications, minimizing stress on piping infrastructure.

Through these trusted partnerships, Summers Rubber delivers reliable, customized solutions for water treatment facilities, enhancing performance and longevity.

Common FAQs About Selecting Gaskets and Expansion Joints for Water Treatment Applications

1. What factors should be considered when selecting a gasket for a water treatment plant?

Key factors include chemical compatibility, pressure ratings, temperature resilience, and adherence to industry standards such as AWWA and NSF. Choosing the right material ensures durability, efficiency, and reduced maintenance costs.

2. What types of gaskets are best suited for chlorinated water applications?

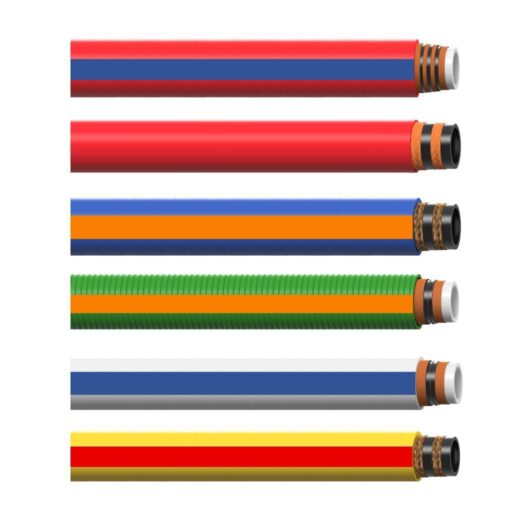

PTFE, EPDM, and NSF-approved rubber gaskets are highly recommended for chlorinated water systems due to their superior chemical resistance and long-lasting performance.

3. Why are expansion joints essential in water treatment facilities?

Expansion joints absorb thermal expansion, vibration, and pipe movement, reducing mechanical stress on pipelines. This prevents stress-related failures and extends the lifespan of piping systems.

4. What materials are commonly used in water treatment expansion joints?

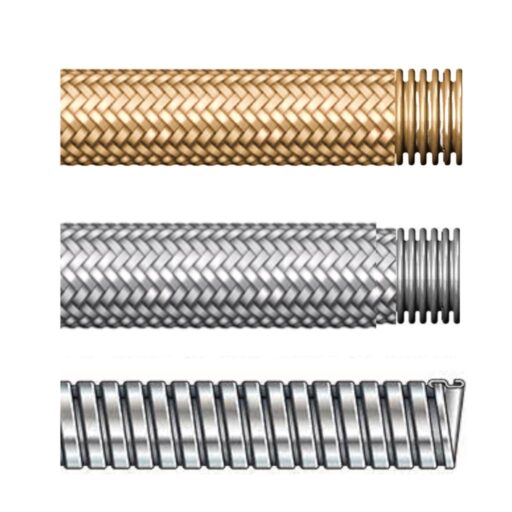

Common materials include EPDM, Neoprene, and PTFE-lined rubber, all of which offer excellent resistance to water, harsh chemicals, and extreme temperature fluctuations.

5. How often should gaskets and expansion joints be inspected and replaced?

Routine inspections should be performed every 6 to 12 months, depending on operating conditions. Any visible signs of wear, cracking, or leakage should prompt immediate replacement to prevent system failures.

Optimize Water Treatment Operations with Summers Rubber

Selecting the right gaskets and expansion joints is essential for maintaining safety, efficiency, and long-term reliability in water treatment facilities. With trusted partnerships from leading manufacturers like Gasket Resources, Garlock, Proco, and Holtz Rubber, Summers Rubber provides premium sealing solutions designed to meet the rigorous demands of the water treatment sector.

Looking for Expert Guidance?

Contact Summers Rubber today to find the best gaskets and expansion joints for your water treatment facility and ensure peak system performance!