In today’s competitive food and personal care manufacturing landscape, ensuring product purity and line efficiency is non-negotiable. Aflex’s Corroline+ and Fabline metal hoses deliver unparalleled performance in handling corrosive chemicals, CIP solutions, and critical sanitary fluids—keeping your operations running smoothly and compliant with the highest industry standards.

Key Benefits of Aflex Corroline+ & Fabline Hoses

- Corrosion Resistance & Chemical Compatibility

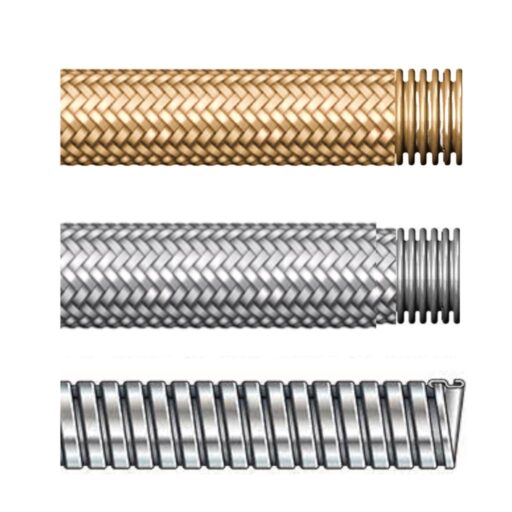

- Corroline+ features a PTFE liner bonded to 316L stainless steel braid, protecting against aggressive acids, alkalis, and cleaning agents commonly used in food and CPG lines.

- Sanitary Design for Zero Contamination

- Fabline offers a smooth-bore, crevice-free interior that meets EHEDG and FDA standards, preventing bacterial harborage and ensuring easy Clean-In-Place (CIP) cycles.

- Superior Flexibility & Vibration Damping

- Both series absorb pump pulsation and vibration, reducing mechanical stress on pumps and valves, and extending equipment life.

- Wide Temperature Range & Pressure Ratings

- Operate from –54 °C to 204 °C (–65 °F to 400 °F) with Corroline+, and up to 150 °C (302 °F) with Fabline, covering steam, hot water, and chilled fluids.

- Custom Configurations

- Available in lengths up to 10 m with various end-fittings (tri-clamp, threaded, flanged), tailored to your skid layout.

Real-World Applications

- Dairy & Beverage: Transfer milk, juice, and CIP chemicals with zero flavor carryover.

- Bakery & Confectionery: Handle syrups and cleaning agents without hose degradation.

- Personal Care & Cosmetics: Convey lotions, creams, and solvents in a contamination-free line.

Implementing Aflex metal hoses means fewer production interruptions, faster maintenance cycles, and compliance confidence—letting you focus on quality and output.

FAQs

- What makes Corroline+ superior for corrosive fluids?

Corroline+’s bonded PTFE liner and 316L braid resist chemical attack and minimize permeation, extending hose life in aggressive environments. - Is Fabline suitable for aseptic processes?

Yes—Fabline meets EHEDG and FDA guidelines with its smooth interior and stainless exterior, ensuring hygienic fluid transfer. - How fast can I install and replace these hoses?

Standard tri-clamp fittings and pre-assembled lengths enable quick swap-outs, typically under 30 minutes per hose. - Can I steam-sterilize these hoses?

Both Corroline+ and Fabline withstand steam up to their maximum temperature ratings for effective sterilization. - Do Aflex hoses require special maintenance?

Routine visual inspections and CIP cycles are generally sufficient; no special tools are needed. - What pressure ratings are available?

Corroline+ is rated up to 40 bar (600 psi), while Fabline handles up to 16 bar (230 psi), depending on size. - Are custom hose assemblies available?

Absolutely—lengths, fittings, and protective covers can be tailored to your exact specifications. - Where can I source genuine Aflex replacements?

Contact us today for Aflex products.