In beverage production, maintaining liquid purity is absolutely essential. A top-tier sanitary hose ensures that beer, wine, juice, or spirits remain uncontaminated from brewing to bottling. Continental (now part of the Summers Rubber portfolio) offers hoses with smooth, plasticizer-free liners designed specifically for the rigorous demands of brewery and beverage plants.

These hoses comply with national and global hygiene standards—including CIP (Clean-In-Place) compatibility—to endure aggressive cleaning cycles without degrading. That makes them ideal for transferring a wide range of beverages: beer, wine, liquor, soft drinks, and fruit juices.

Key Benefits of Continental-Designed Brewery Hose

- Ultra-smooth, compliant lining – Prevents contamination and preserves taste by avoiding plasticizers and minimizing surface roughness.

- Fully CIP-cleanable – Built to tolerate regular sanitation without risking material breakdown or pinch points.

- Robust testing and certifications – Manufactured in controlled facilities to meet FDA, USDA, and 3-A regulatory standards.

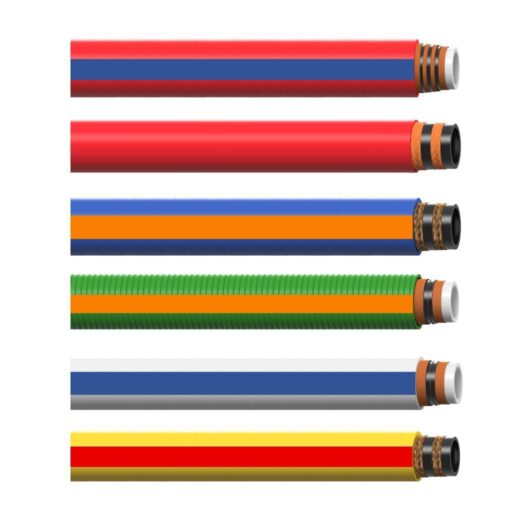

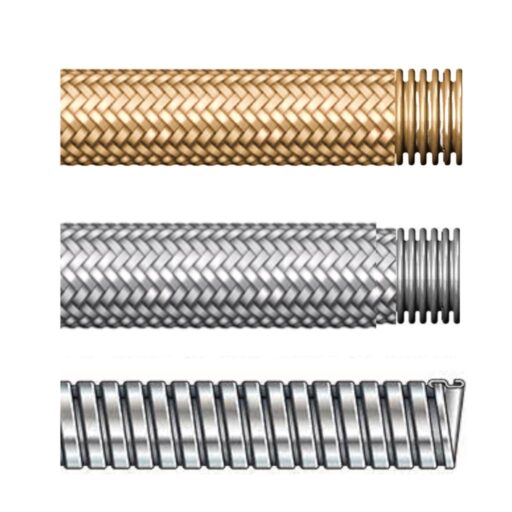

- Flexible, fit-for-purpose options – Hose types available for brewery, filling, dairy, and potable water applications; compatible with standard sanitary fittings.

Why Summers Rubber Adds Value

- Localized Inventory – With stocking warehouses in key regions, Summers Rubber ensures quick access to brewery hoses when you need them most.

- Expert Hose Assembly – We offer ASME-certified crimping, banding, and sanitary coupling to deliver leak-proof, clean hose setups.

- On-site Testing Services – Using Hose Asset Management systems, we verify hose integrity and schedule maintenance before any failures occur.

- Complete Support – Need sanitary fittings, clamps, or washdown systems? We offer full solutions tailored to beverage operations.

How to Choose the Right Hose

| Consideration | Why It Matters |

|---|---|

| Media Compatibility | Alcohol, fruit juice, etc. may need specific hose compounds to avoid degradation. |

| Cleaning Protocols | High-temp or aggressive CIP requires hoses with chemical and temperature resistance. |

| Pressure & Bend Needs | Tight spaces call for flexible hoses like ExtremeFlex; larger transfers may prefer hose with reinforced spiral rods (e.g., Vintner). |

| Sanitary Standards | Ensure hoses meet FDA, USDA, 3-A, and other relevant regulations for contact with consumables. |

Summary

Investing in premium brewery hoses from Summers Rubber (powered by Continental technology) ensures your beverage production runs efficiently, safely, and without compromise. Precision-engineered liners, compatibility with CIP protocols, proven hygienic performance, and production-grade flexibility combine to protect product quality and streamline operations.

FAQs

What makes these hoses CIP-compatible? They feature smooth, plasticizer-free liners and rugged inner construction built to withstand repeated caustic and high-temperature cleaning cycles.

Can one hose work for beer, wine, and juice? Yes—Continental offers multipurpose hoses designed for use across varied beverage types while maintaining taste neutrality.

What sanitary fittings are standard? Tri‑Clamp (Tri‑Clover) fittings are widely supported, along with swaged and half-shell connections for secure, hygienic hose assemblies.

How durable are these hoses? Manufactured with premium materials and strict quality controls, they meet high-pressure safety standards and resist abrasion, ozone, and chemical attack.

Does Summers Rubber handle hose assembly? Yes—our facilities offer professional crimping, banding, and testing, plus on-site inspections to ensure full operational reliability.

How often should hoses be replaced? Replacement depends on usage and cleaning cycles. With monitored hose asset systems, we recommend proactive replacement at the end of service life to prevent downtime.

Are hoses traceable and certified? Absolutely—each hose comes with certifications for FDA, USDA, 3-A compliance, and manufacturing traceability.

Can these hoses be customized? Yes—Summers Rubber can supply bespoke assemblies featuring specialty fittings, specific lengths, labels, or protective covers for washdown environments.