Dust suppression is a critical concern in Ohio’s aggregate mining industry, impacting worker safety, equipment performance, and regulatory compliance. At Summers Rubber, we provide industry-leading dust suppression solutions from Benetech, helping mining operations implement effective and compliant dust control strategies.

The Risks of Silica Dust Exposure

Exposure to silica dust can lead to severe respiratory diseases, including:

- Silicosis – A debilitating lung disease caused by prolonged inhalation of fine silica particles, leading to lung scarring and reduced lung function.

- Lung Cancer – Long-term exposure to silica dust is a known carcinogen, significantly increasing the risk of lung cancer in exposed workers.

- Chronic Obstructive Pulmonary Disease (COPD) – Silica dust exposure can lead to chronic inflammation in the lungs, resulting in breathing difficulties, reduced oxygen intake, and long-term health complications.

How Benetech’s Dust Suppression Systems Improve Safety & Efficiency

- Wet Dust Suppression Systems – Uses water-based systems to control airborne dust at primary dust generation points, such as crushers and conveyor belts. By adding moisture to the material, it prevents dust particles from becoming airborne and enhances workplace air quality.

- Foam Suppression – A cost-effective solution that encapsulates fine dust particles with a minimal amount of water. Foam suppression technology effectively controls airborne dust while reducing overall water consumption, making it ideal for environments with limited water resources.

- Dust Control Chemicals – Specially formulated chemical agents enhance dust suppression efficiency by improving moisture retention and preventing material buildup on equipment. These chemicals help control fugitive dust while also reducing the frequency of maintenance and cleaning requirements.

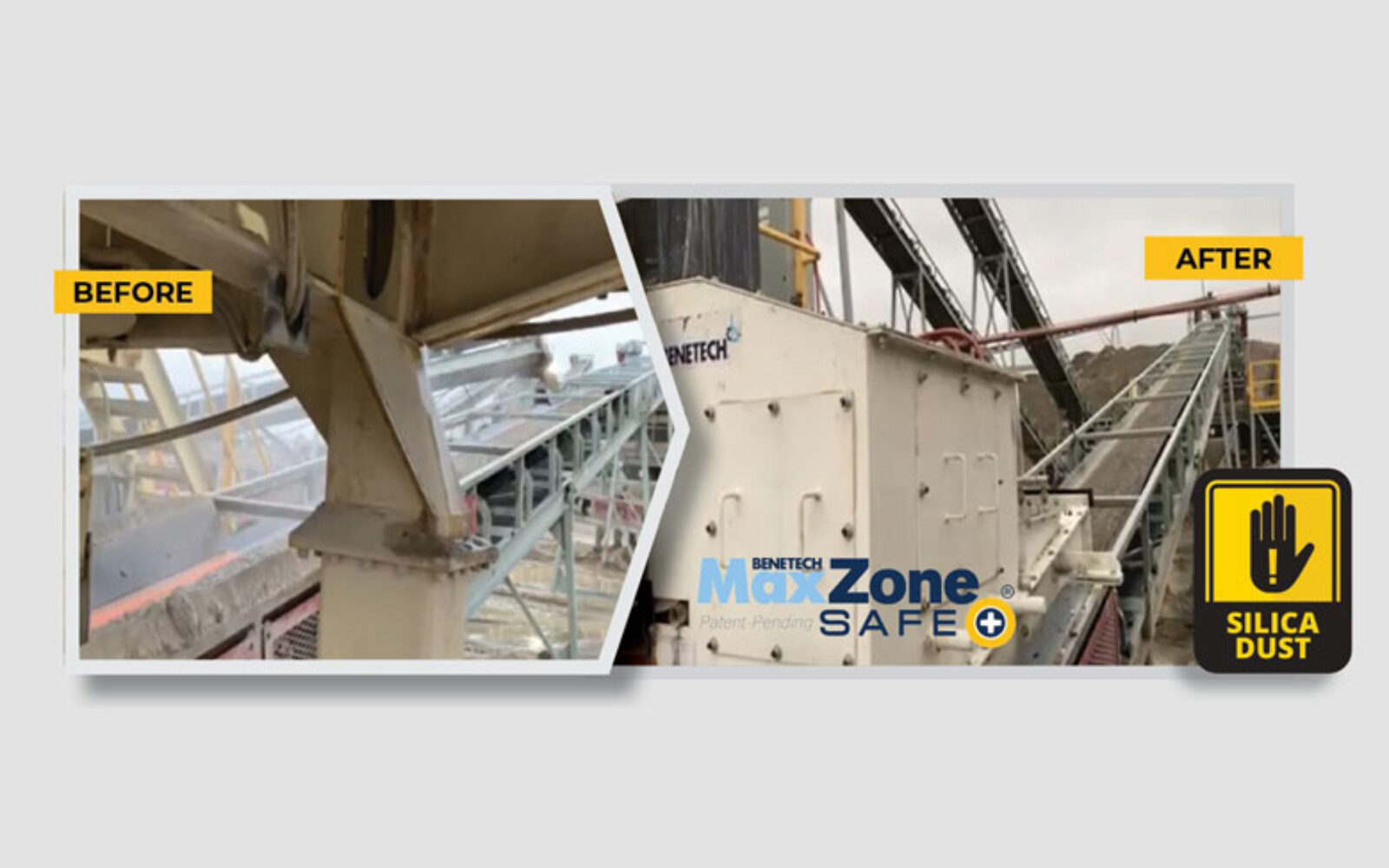

- Enclosed Transfer Points – By enclosing conveyor transfer points and loading areas, dust escape is minimized, protecting workers and surrounding equipment from exposure. Enclosures also help comply with regulatory dust limits and improve overall air quality within mining facilities.

Key Benefits of Benetech Dust Suppression

- Improves worker health and safety – Reduces airborne dust hazards that contribute to respiratory illnesses, ensuring a safer work environment for employees.

- Extends equipment life – Minimizes dust accumulation on machinery, preventing excessive wear and reducing the need for frequent maintenance and repairs.

- Ensures compliance – Helps mining operations meet stringent OSHA, EPA, and MSHA regulations, avoiding costly fines and legal issues related to dust exposure.

- Enhances operational efficiency – Reduces maintenance requirements, unplanned downtime, and the costs associated with excessive equipment cleaning and repairs.

Why Choose Summers Rubber for Dust Suppression Solutions?

- Expertise in Ohio’s mining regulations – Our team understands local and federal regulations, ensuring your dust suppression strategies align with compliance standards while maximizing safety.

- Customized dust control strategies – We offer tailored solutions to address the specific challenges of each mining site, optimizing efficiency and effectiveness.

- Ongoing support & maintenance programs – Our maintenance and tracking programs help ensure that dust suppression systems remain effective over time, preventing failures and unexpected downtime.

Need Reliable Dust Control Solutions?

Looking to enhance safety, compliance, and efficiency in your mining operations? Contact Summers Rubber today for industry-leading Benetech dust suppression solutions.