The injection molding industry depends on high-performance hoses, expansion joints, and hydraulic components to maintain efficiency and reduce downtime. Whether managing plastic pellet transfer, optimizing hydraulic systems, or maintaining material flow, selecting the right products is critical to achieving consistent and high-quality production output. Summers Rubber is Ohio’s premier supplier, providing a one-stop shop for all injection molding facility needs.

Why Choose Summers Rubber for Injection Molding Applications?

At Summers Rubber, we offer a diverse range of high-quality products specifically designed to meet the unique demands of injection molding operations:

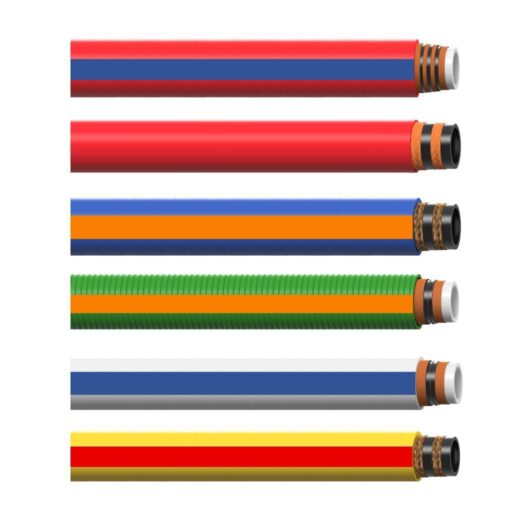

- Kuriyama PVC & Urethane Material Handling Hoses – Designed for efficient plastic pellet transfer, these hoses offer superior abrasion resistance to withstand continuous high-volume movement, preventing blockages and material degradation. Their lightweight yet durable construction allows for easier handling and installation within facility systems.

- Viking Conveyor Belts – Essential for smooth material transfer within injection molding operations, Viking Conveyor Belts provide high heat and abrasion resistance. These belts help optimize the movement of raw materials and finished products, ensuring greater system efficiency and reliability.

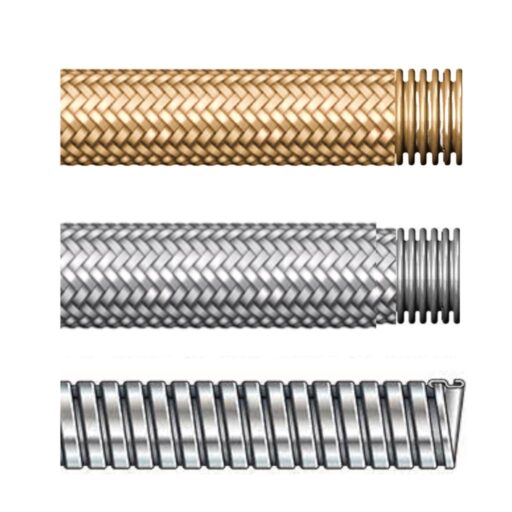

- Proco Expansion Joints – Expansion joints help absorb movement and reduce strain on piping systems, preventing stress-related failures in high-pressure and high-temperature applications. Proco’s durable expansion joints extend equipment lifespan by compensating for vibration, thermal expansion, and misalignment in industrial systems.

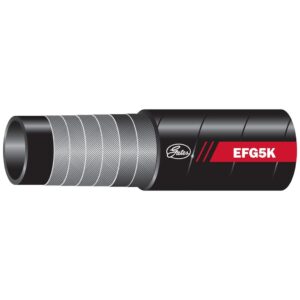

- Gates Hydraulic Hose & Fittings – A critical component for powering injection molding machinery and auxiliary equipment, Gates hydraulic hoses provide high-pressure performance with superior flexibility. These hoses resist extreme temperatures and exposure to industrial fluids, ensuring reliable power transmission for molding operations.

With Summers Rubber, injection molding facilities across Ohio gain access to industry-leading, high-performance products that keep operations running at peak efficiency.

Common Questions About Injection Molding Hose & Expansion Joint Selection

1. What type of hose is best for plastic pellet transfer?

Kuriyama PVC and urethane hoses are the top choices due to their high abrasion resistance, flexibility, and lightweight design. These hoses reduce clogs, minimize material loss, and improve the overall efficiency of plastic pellet handling systems.

2. Why is the Viking Conveyor Belt recommended for injection molding facilities?

Viking Conveyor Belts provide exceptional wear resistance and strength, making them ideal for transferring raw materials and finished products in high-output environments. Their durability ensures long-term operational reliability with minimal maintenance requirements.

3. How do expansion joints benefit injection molding systems?

Proco Expansion Joints protect equipment by absorbing vibration, thermal expansion, and system movement. This prevents stress-related pipe failures, extends system longevity, and ensures smooth operation with minimal downtime.

4. What hydraulic hose should I use for injection molding machines?

We recommend Gates Hydraulic Hoses for injection molding machinery due to their high-pressure capabilities, superior flexibility, and resistance to extreme temperatures and industrial fluids. These hoses ensure consistent power delivery, enhancing overall equipment performance and lifespan.

Why Should Injection Molding Facilities Choose Summers Rubber?

- Industry Expertise – Our team has extensive knowledge of injection molding operations and can provide tailored recommendations for your facility.

- Premium Brands – We supply top-quality hoses, expansion joints, and conveyor belts from trusted manufacturers, ensuring superior performance and durability.

- Custom Solutions – Whether you need specialized fittings, custom-cut conveyor belts, or high-pressure hydraulic solutions, we offer customized products to meet your facility’s unique requirements.

- Fast and Reliable Service – Our extensive inventory and quick turnaround times mean you get the products you need when you need them, minimizing downtime and improving operational efficiency.

Optimize Your Injection Molding Operations with Summers Rubber

Selecting the right hoses, expansion joints, and hydraulic components is crucial for maintaining efficiency and longevity in injection molding facilities. Whether you need high-performance material handling hoses, reliable expansion joints, or durable hydraulic solutions, Summers Rubber has the expertise and product range to keep your operations running at peak performance.

Looking for the Best Injection Molding Solutions?

Contact Summers Rubber today for expert recommendations and high-quality industrial solutions tailored to your injection molding applications!