Efficient and reliable material handling is essential in industries that rely on conveyor systems. Whether in mining, power generation, aggregate processing, or bulk material handling, transfer points are a critical component that impacts productivity, safety, and operational costs. Summers Rubber is proud to be a premier supplier of Benetech Global’s Engineered Transfer Chutes, providing cutting-edge solutions that optimize conveyor performance and reduce material spillage, dust, and wear.

Why Engineered Transfer Chutes Matter

A poorly designed transfer point can lead to numerous operational challenges, including:

- Material Spillage: Excessive spillage causes product loss, safety hazards, and unnecessary cleanup costs.

- Dust Emissions: Airborne dust contributes to health and safety concerns, regulatory compliance issues, and equipment wear.

- Conveyor Belt Damage: High-impact material transfers accelerate wear on belts, idlers, and pulleys, increasing maintenance expenses.

- Flow Disruptions: Material blockages and irregular flow patterns reduce system efficiency and throughput.

Benetech’s Engineered Transfer Chutes solve these issues by utilizing advanced material flow technology, ensuring smooth transitions from one conveyor to another while minimizing impact, dust, and spillage.

Benetech Engineered Transfer Chutes: The Smart Solution for Material Handling

Benetech’s Engineered Transfer Chutes are designed with custom-engineered flow control to optimize the movement of bulk materials. Their advanced design offers several key benefits:

1. Material Flow Optimization

- Minimizes Turbulence: By controlling the trajectory of material, Benetech chutes ensure a steady and consistent flow that reduces belt wear and energy consumption.

- Custom-Engineered Designs: Each chute is tailored to fit your specific conveyor system, material type, and operational requirements.

2. Dust and Spillage Reduction

- Enclosed Designs: Engineered chutes contain material within the system, preventing excessive dust emissions and reducing the need for dust suppression systems.

- Controlled Drop Heights: Minimizing free-fall distances reduces impact and material degradation, ensuring efficient transport.

3. Longer Conveyor Component Lifespan

- Wear Liners for Durability: Benetech chutes include replaceable liners that protect against abrasive materials and prolong the chute’s service life.

- Reduced Belt Wear: By controlling the loading angle and velocity, engineered chutes prevent premature conveyor belt damage.

4. Improved Safety & Compliance

- Minimizing Dust Hazards: Engineered chutes help facilities meet OSHA and MSHA safety standards by reducing airborne dust exposure.

- Safer Work Environments: Less spillage and dust accumulation mean fewer slip hazards and maintenance-related risks.

Frequently Asked Questions About Engineered Transfer Chutes

1. What industries benefit from engineered transfer chutes?

Benetech’s engineered chutes are used across multiple industries, including:

- Mining & Quarrying

- Cement & Aggregate Processing

- Power Generation (coal handling)

- Steel & Foundries

- Bulk Terminal Operations

2. How do engineered transfer chutes improve conveyor efficiency?

Engineered chutes direct material flow more efficiently, ensuring smoother transitions between conveyor belts. This reduces blockages, prevents spillage, and minimizes maintenance downtime, ultimately increasing overall system throughput.

3. Can Benetech chutes be customized for existing conveyor systems?

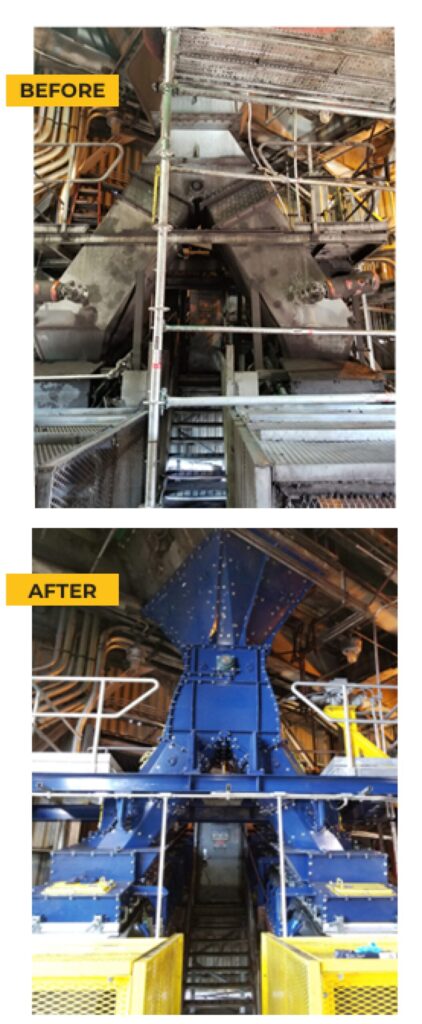

Yes. Each transfer chute is custom-engineered to fit the exact specifications of your conveyor layout, material type, and operational needs. Upgrades and retrofits are available for existing systems.

4. How do engineered transfer chutes reduce maintenance costs?

By controlling material movement and reducing high-impact areas, Benetech chutes extend the life of conveyor belts, idlers, and pulleys while reducing the frequency of repairs and cleanups.

5. Are Benetech engineered transfer chutes compliant with safety regulations?

Yes. Benetech’s designs help facilities comply with OSHA, MSHA, and EPA dust control standards, ensuring a safer work environment and regulatory compliance.

Summers Rubber: Your Trusted Source for Benetech Global’s Transfer Chutes

As a leading supplier of conveyor system solutions, Summers Rubber is proud to offer Benetech Global’s Engineered Transfer Chutes to our customers. With a strong commitment to efficiency, safety, and reliability, we provide custom solutions that enhance conveyor performance and extend the lifespan of critical components.

Why Choose Summers Rubber?

- Expertise in Conveyor Systems – We understand the challenges faced in material handling industries and can recommend the best transfer chute solutions for your operation.

- Industry-Leading Products – As a premier supplier of Benetech Global products, we ensure our customers receive high-quality, engineered solutions.

- Custom Solutions & Support – Our team works closely with customers to provide custom-fitted transfer chutes designed for their exact conveyor needs.

If you’re experiencing conveyor system inefficiencies due to dust, spillage, or excessive belt wear, it’s time to upgrade to Benetech’s Engineered Transfer Chutes.

Contact Summers Rubber today to learn how we can help improve your conveyor performance with Benetech Global solutions!